Heat exchangers

All heat transfer processes are required to be effective and reliable, independently of external conditions. This is of particular importance in power plants. Sahala Hex’s heat exchangers cover all the needs and requirements imposed by the energy industry’s processes. Regardless of the power plant type – from nuclear power generation to biopower plants, refinery, chemical plant or paper and pulp mill.

Our products and services

Heat exchangers:

- manufacture of heat exchanger, thermotechnical dimensioning and design

- repair and maintenance of heat exchangers

- spare parts for thee heat exchangers

Pressure equipment:

- manufacture and design of pressure equipment and pressure vessels

- repair and maintenance of pressure equipment and pressure vessels

Kuorimarumpujen ja prosessirumpujen varaosat

Konepajatyöt

Efficient and reliable heat exchanger solutions

The company’s development work extending over many decades, combined with its experience of hundreds of deliveries, have made our heat exchangers’ thermodynamical solutions efficient and economical. These solutions enable the optimal heat balance management for the various power plant types – in all production situations.

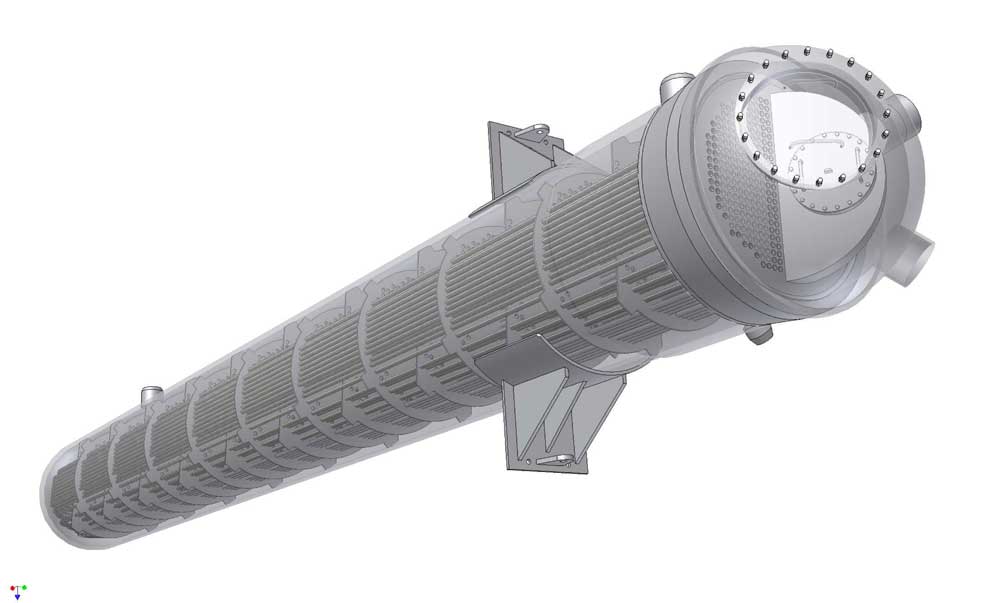

Reliability is a central element in efficiency. Our material, construction and dimensioning solutions are based on our vast experience of the special requirements imposed by power plant processes. We also develop our manufacturing methods on a continual basis. An example of this policy is the fully automatic MaTIC 500 orbital welding system, which is used to connect heat exchanger tubes to tube sheets. The new technology enables us to always produce high quality welds, with an identical quality level repeated time after time.

Sahala Hex product palette covers a power plants all heat exchangers and the feed water tank.

Special process requirements and material properties are also observed in our design and manufacture which uses state-of-the-art technology as required, including vibration analysis for the mathematical modelling of equipment vibration and the Finite Element Method (FEM) for material strength calculations. We also have a complete set of approved welding methods covering a wide variety of materials and process requirements.

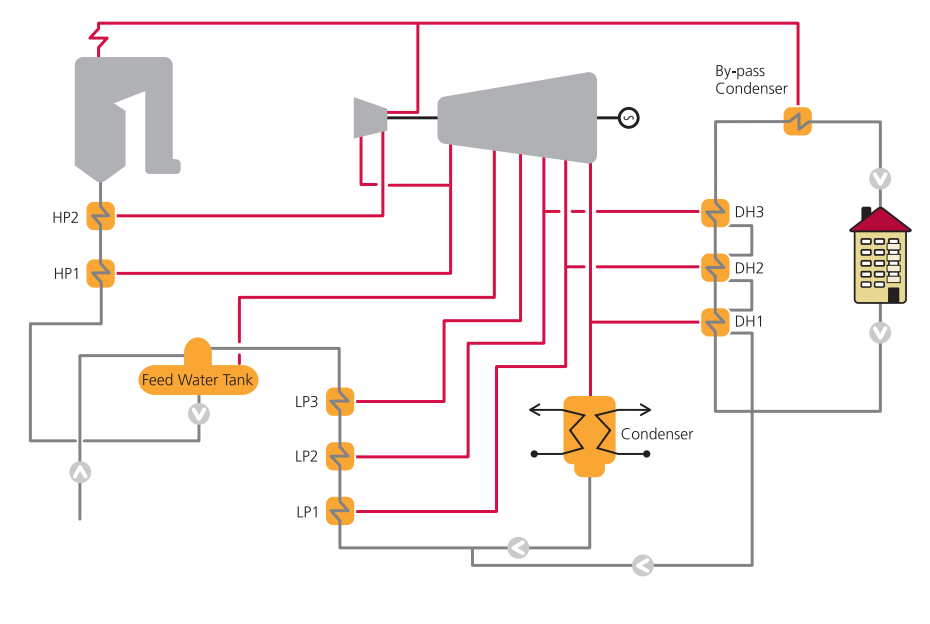

Power plants

In addition to efficiency, energy production requires extreme reliability. This means that all materials used in the manufacture of power plant equipment must be selected individually, in accordance with each installation’s special requirements. Nevertheless, mere material selection is not enough – you must also master the manufacturing processes and particularly the welding methods, in compliance with the process-specific special conditions.

Due to the great variety of power plant equipment requirements, we use a wide selection of raw materials, covering all the requirements imposed by power plant processes.

A few examples of the metals we process include:

- carbon steels (CS, LTCS)

- stainless steels

- duplex and super-duplex steels

- super austenitic steels (6Mo)

- heat-resistant steels (e.g. 1.25Cr 0.5Mo, 2.25Cr 1Mo, 5Cr 0.5Mo)

- compound materials

- nickel alloys (e.g. Alloy 825, Alloy 625, Monel 400)

- aluminium

- titanium

Our products

- high-pressure feed water preheaters

- low-pressure preheaters

- heat exchangers for district heating

- condensers and auxiliary condensers

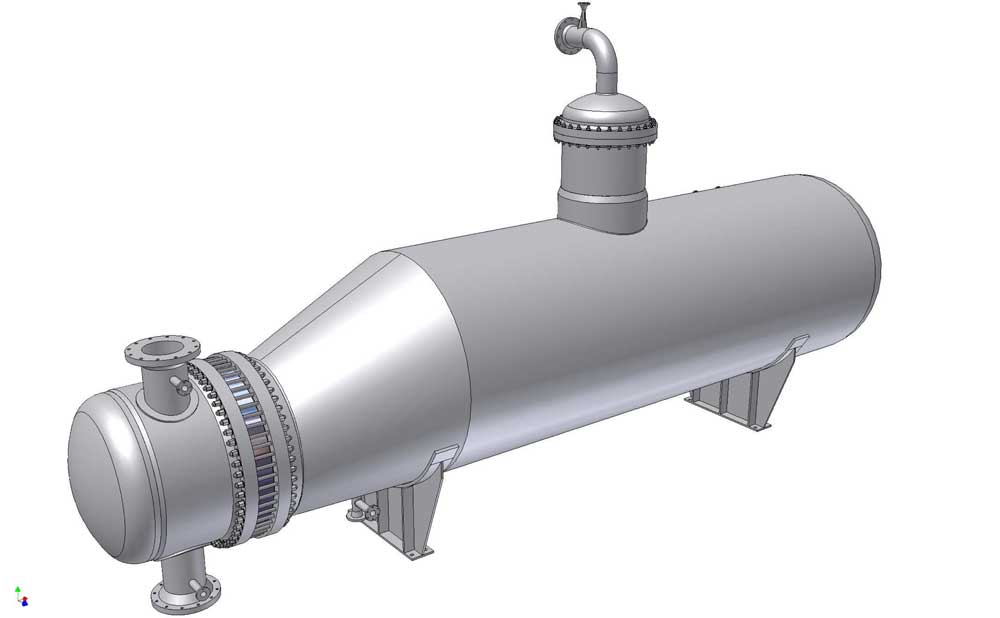

- feed water tanks

- steam accumulators

The petrochemical and chemical processes require individual solutions

Sahala Hex’s solid process experience of the petrochemical and chemical processes and their material requirements, plus the company’s consistent development of products and manufacturing methods guarantee that our individually designed equipment will function reliably and efficiently in any installation.

As the process conditions are currently much harsher than ever before, the manufacturing materials must be selected individually, in accordance with each installation’s special requirements.

Nevertheless, mere material selection is not enough – you must also master the manufacturing processes and particularly the welding methods, in compliance with the process-specific special conditions.

Our products

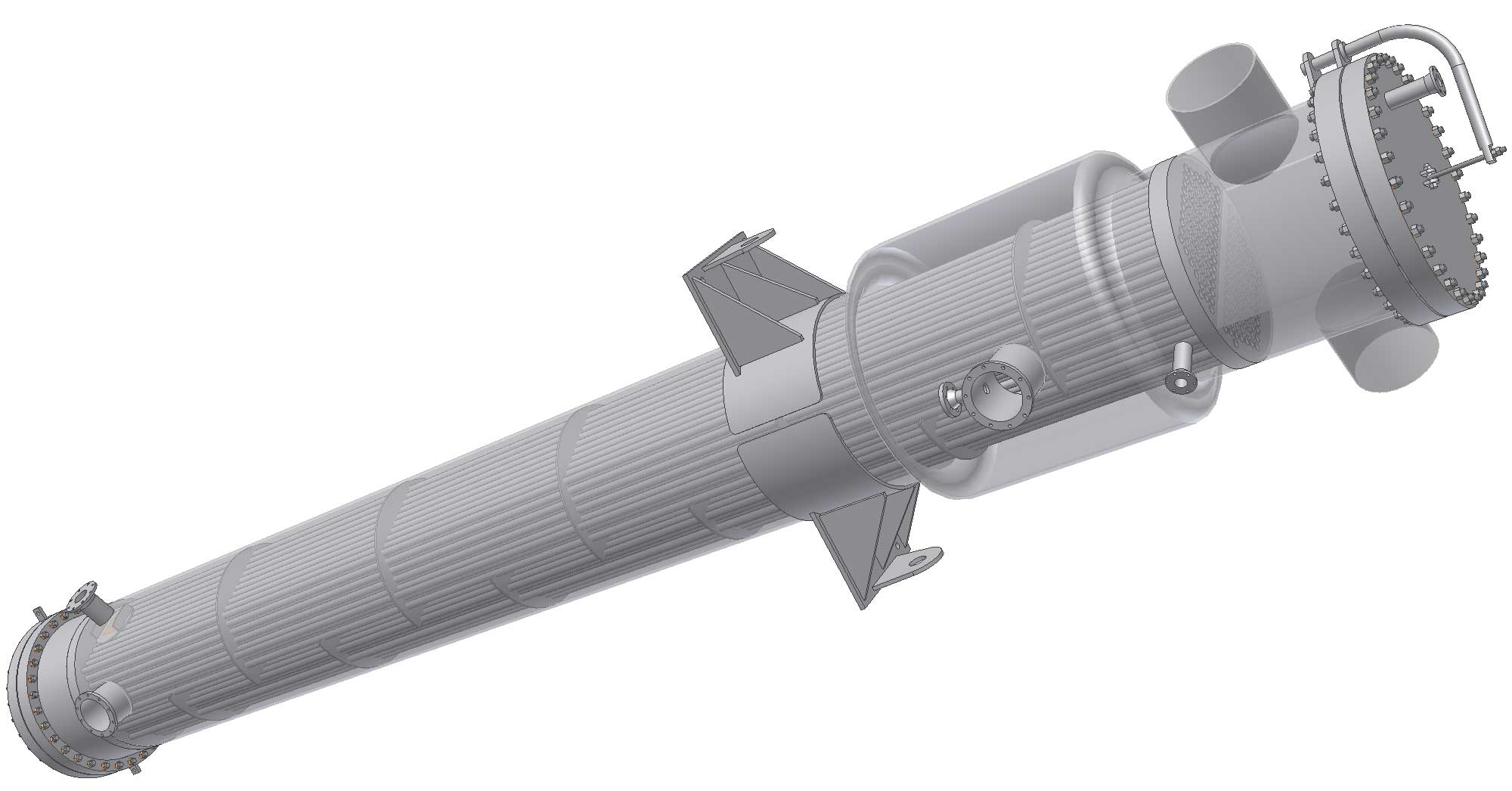

- tubular heat exchangers

- feed water tanks

- steam accumulators

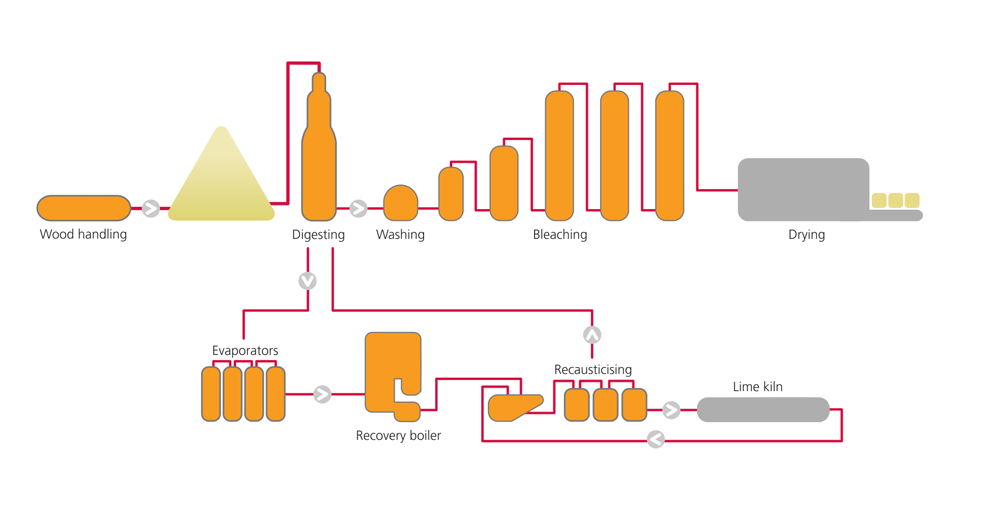

Paper and pulp industry

The pulp and paper industry has been among Sahala Hex’s key customers for more than 50 years. Our solid process experience of pulp mill processes and their material requirements, plus the company’s consistent development of product and manufacturing methods guarantee that our individually designed equipment will function reliably and efficiently in any installation.

An example of this policy is the fully automatic MaTIC 500 orbital welding system, which is used to connect heat exchanger tubes to tube sheets. The new technology enables us to always produce high quality welds, with an identical quality level repeated time after time.

Mere thermodynamics is not enough for pulp mill heat transfer solutions

The tough pulp mill conditions impose extremely exacting requirements on heat exchangers. Extremely high pressure and temperature levels are not the only challenge – pulp mill heat exchangers must handle various liquors, contaminated condensates and other substances whose composition, impurities and viscosity vary significantly. These process variables and disturbances require much more than optimal thermodynamics in terms of heat exchanger constructions.

Achieving total control and true mastery of these factors in heat exchanger development, design and dimensioning is impossible without solid, in-depth experience of pulp process behaviour. Sahala Works has gained this experience from thousands of heat exchangers over the past decades.

Our products

- tubular heat exchangers

- feed water tanks

- steam accumulators

Sahala Hex’s heat exchangers cover wood handling, digesting, washing, bleaching, recovery boiler, evaporators and recaustising.

Who maintains the heat exchangers?

We. We maintain heat exchangers manufactured by old brands such as Sento, Ahlström, Högfors, HögforsSahala and Sahala Works with decades of solid professionalism. When it comes to heat exchangers, many people may think of old heat exchanger manufacturers such as, Sento, Ahlström, Högfors, HögforsSahala and Sahala Works. There are hundreds of heat exchangers manufactured by these old brands in Finland and other Nordic countries, which sometimes require maintenance.

As the current owner of the heat exchanger business, we manufacture new heat exchangers, but also maintain old ones. We handle heat exchanger maintenance, spare parts manufacturing and installation in cooperation with our new heat exchanger manufacturing unit, SSG Sahala Hex.

We offer a wide range of maintenance services for heat exchangers, always tailored to the customer’s needs. If necessary, we can replace the device completely, or only a part of it. For example, we can pipe the heat exchanger pipe group completely new, or replace only part of the pipes. We also take care of smaller units, such as dismantling a damaged chamber and delivering a new chamber with its installations.